3S Swiss Solar Systems, a subsidiary of Meyer Burger Technology AG, is collaborating with emergent Korean solar company, KISCO. By the spring of 2011, with an integrated 3S Modultec 65MW production line, KISCO will be producing highly efficient crystalline solar modules only 6 months after signing the contract. A further extension of their production capacity with equipment from Lyss is also planned. KISCO aims to conquer a growing share of the European and U.S. markets with ‘GETWATT’, a brand already established in the thin-film solar industry. The new solar crystalline production plant will be the first of its kind in Korea.

The 65 MW production line is geared to the specific needs of the Korean client and can be installed at relatively low cost and within a short time frame. A gradual expansion of annual production capacity up to 240MW is already in the planning, with further investments to follow. The outstanding quality of their equipment and the comprehensive service offered by the company based in Lyss, Switzerland, together with their experience in the field of module production, were the determining factors for KISCO in their decision to go with the 3S Modultec brand. “Our corporate philosophy is to offer products of the highest quality to our customers. The tender from 3S won us over, as it will enable us to achieve first-class product quality here whilst at the same time receiving intensive on-site support from experienced specialists”, says Byung-Je Lee, COO of GETWATT.

Know-how transfer and support service for rapid and successful ramp-up

The production line was sold in conjunction with a comprehensive range of services: know-how transfer, an on-site training package for employees, and guaranteed certification of the modules made on the production line, all of which will enable the client to begin production of high-quality modules within a short time frame. One of the benefits to KISCO will be the 3S certification service in collaboration with TÜV Rheinland. With this quick and proven process, together with the tailored, company-specific service package, KISCO will reduce its time-to-market by many valuable months.

The production equipment, to be installed at the headquarters of KISCO’s Energy Division near Seoul, consists of an automated string soldering system from Somont, a laminating line from 3S Modultec and a module tester from Pasan. The entire capital equipment will be shipped before the end of this year.

Comprehensive expertise in solar module production and the modular concept

3S Modultec offers integrated production lines for solar module production with varying degrees of automation. The modular assembly of the lines allows for relatively low-cost expansion of capacity within a short space of time. Optimal calibration of the production line equipment and unparalleled certification support in collaboration with the TÜV organisation, together with comprehensive process training, form the perfect basis for rapid project execution. With 3S Modultec production lines, manufacturers of solar modules world wide are able to produce modules with a minimized cost of ownership.

About KISCO/GETWATT

www.getwatt.co.kr

KISCO is a Korean company that has been successfully developing and producing steel products for 50 years. Since 2008, the company has also been active in the solar industry under the brand name “Getwatt”. Up until now, KISCO’s Solar Division has been producing solar modules for the Asian and European markets using thin-film technology on a 20MW production line. By expanding its production capacity for crystalline solar modules, the company is pursuing its goal of becoming a significant player in the international PV industry. They plan to gradually step up their future activities in the solar business, in order to supply an increasing number of international customers with high quality solar modules.

Contact:

Dr. Anja Knaus

3S Swiss Solar Systems AG

Head of Communications

fon +41(0)32 391 1136 fax +41(0)32 391 1112

anja.knaus@3-s.ch

www.3-s.ch

About 3S Swiss Solar Systems Ltd.

www.3-s.ch

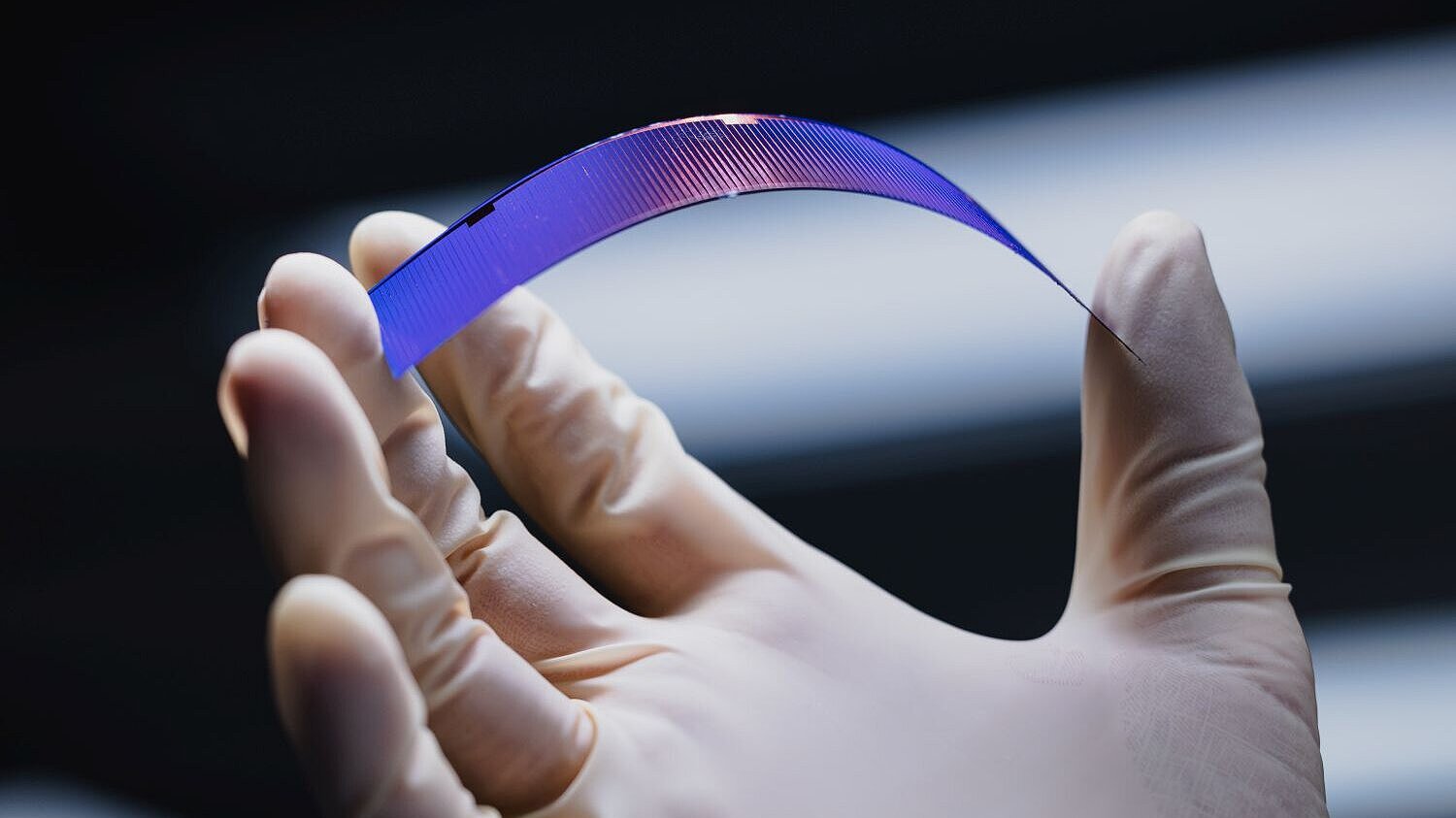

3S Swiss Solar Systems has for years been the world's technological market leader in the field of laminating. With fully automatic laminating lines from Lyss, module manufacturers worldwide today produce photovoltaic modules of highest quality. Since 2008, 3S Swiss Solar Systems has been integrating various machines into turnkey production lines for the manufacture of solar modules with greatly differing degrees of automation. The equipment for solar module producers is now being marketed under the brand-name of 3S Modultec.

Our company also develops and produces, under the newly introduced brand 3S Photovoltaics, trend-setting, building-integrated solar systems and has specialised here in solar modules for roofs, facades and shading solutions. Solar modules from our factory in Lyss are the perfect synthesis of a robust, weatherproof building shell and efficient, environmentally friendly energy production.

3S Swiss Solar Systems with the brands of 3S Modultec – Module Solutions and 3S Photovoltaics – Solar Building Technologies has been a subsidiary of Meyer Burger Technology AG since January 2010.

About Meyer Burger Technology Ltd

www.meyerburger.com

Meyer Burger is a leading and globally active technology group for innovative systems and processes for cutting and handling crystalline and other high-grade materials.

The machines, competences and technologies of the different companies within the group are used in the solar industry (photovoltaics), semiconductor and optical industry. The thinnest wafers made from silicon, sapphire or other crystals are required in these three markets to manufacture solar modules, switching circuits or high-performance LEDs. The group’s core competences are made up of a whole range of production processes, machines and systems that are used within the value chain in the manufacture of high quality wafers. Since the merger in January 2010 with 3S Industries Ltd, the worldwide leader in turnkey production lines and single equipment for the manufacturing of solar modules, the group also covers the entire value chain for solar module production and combines the key technologies of soldering, laminating and testing under one roof. Solar module manufacturers worldwide use the string soldering machines of Somont, the laminating lines of 3S and the testing technologies of Pasan, to produce solar modules whose performance, operating life and quality meet the highest demands. The group’s comprehensive range of products includes a worldwide service network with wear and tear parts, consumables, re-grooving services, process know-how, servicing, after-sales service, training and other services. As a globally active company, the group is represented in Europe, Asia and North America in the respective key markets.

Meyer Burger has its headquarters and the production facility of MB Wafertec (Meyer Burger Ltd) in Switzerland, while the group companies, Meyer Burger Automation GmbH, Hennecke Systems GmbH and AMB Apparate + Maschinenbau GmbH have their headquarters and production facilities in Germany. Diamond Materials Tech, Inc. has its headquarters in Colorado Springs, CO, USA. The production facilities of 3S Modultec, 3S Photovoltaics and Pasan are also located in Switzerland, while Somont is located in Germany. Meyer Burger Group has also subsidiaries and own service centres in Germany, Norway, Spain, USA, China, Japan, Singapore, South Korea and Taiwan. In other important markets, the company relies on selected independent agents. The registered shares of Meyer Burger Technology Ltd are listed on the SIX Swiss Exchange (Ticker: MBTN).

THIS PRESS RELEASE IS NOT BEING ISSUED IN THE UNITED STATES OF AMERICA AND SHOULD NOT BE DISTRIBUTED TO U.S. PERSONS OR PUBLICATIONS WITH A GENERAL CIRCULATION IN THE UNITED STATES. THIS PRESS RELEASE DOES NOT CONSTITUTE AN OFFER OR INVITATION TO SUBSCRIBE FOR, EXCHANGE OR PURCHASE ANY SECURITIES. IN ADDITION, THE SECURITIES OF MEYER BURGER TECHNOLOGY LTD HAVE NOT BEEN AND WILL NOT BE REGISTERED UNDER THE UNITED STATES SECURITIES ACT OF 1933, AS AMENDED (THE “SECURITIES ACT”), OR ANY STATE SECURITIES LAWS AND MAY NOT BE OFFERED, SOLD OR DELIVERED WITHIN THE UNITED STATES OR TO U.S. PERSONS ABSENT REGISTRATION UNDER OR AN APPLICABLE EXEMPTION FROM THE REGISTRATION REQUIREMENTS OF THE UNITED STATES SECURITIES LAWS.

Getwatt production plantpdf commercial news